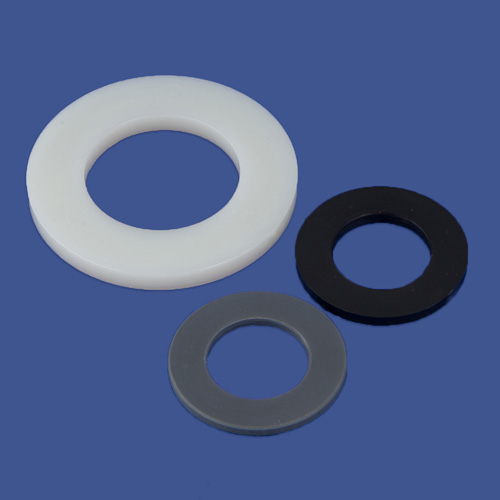

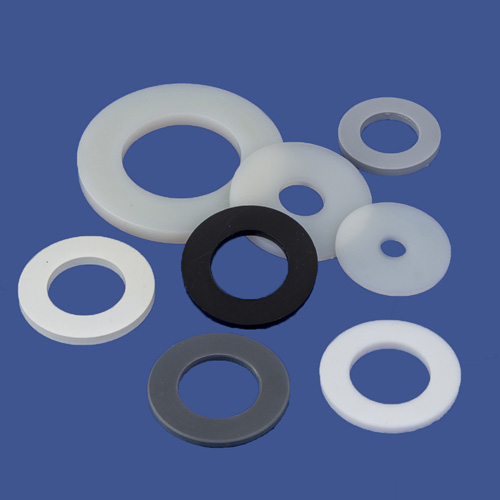

Nylon Washers Other Plastic Washers

Non metal Washers can be used in different applications due to the following key reasons:

- They are durable … these washers can outlast metallic washers in a number of applications. This guarantees long-term cost saving since you won’t replace the washers regularly.

- Better absorption properties; a number of engineering applications are associated with both noise and vibrations. They are excellent when it comes to both noise and shock absorption.

- Resistance to chemicals- Some materials are not affected by most chemicals thus, they neither rust or corrode when exposed to harsh chemicals. They are designed with protective layers which protect them from abrasion.

- Surface friction: they have a low surface friction, thus, they do not deteriorate easily. They can be used in applications where surfaces tend to rub against each other.

- Forming seals – they can compress under pressure which makes them a perfect choice in applications where tight seals are required.

- Insulation – they are excellent insulators, and this has been one of the main reasons why they are used in electrical and electronic components. They are used to install components in temperature-sensitive areas.

- Lightweight – they can be used to replace the metal washers for purposes of reducing overall weight.

Most common Standard is Nylon PA 66 (which is available in Natural or Black Moulded for enhanced UV Resistance). For increased strength 30% Glass Filled Nylon – Black, also available (on request).

Other materials available include Polypropylene, Acetal, PTFE (Teflon), PVC, PVDF, Peek, TPR and Fibre – each with their own specific attributes and uses.

- Metric Natural

- Imperial Natural

- Metric Black

| METRIC (Millimetres) | |||

| NATURAL NYLON | |||

| Size | ID | OD | Thick |

| M2 | 2.2 | 5.0 | 0.3 |

| 2.2 | 5.0 | 0.8 | |

| M2.5 | 2.7 | 6.0 | 0.6 |

| 2.6 | 5.6 | 0.8 | |

| M3 | 3.2 | 7.0 | 0.5 |

| 3.2 | 8.0 | 0.8 | |

| 3.2 | 9.0 | 0.8 | |

| M3.5 | 3.7 | 8.0 | 0.5 |

| 3.7 | 8.0 | 0.58 | |

| M4 | 4.3 | 9.0 | 0.8 |

| 4.3 | 12.0 | 1.0 | |

| 4.3 | 12.0 | 1.2 | |

| 4.3 | 16.0 | 1.5 | |

| M5 | 5.3 | 9.0 | 1.0 |

| 5.3 | 10.0 | 1.0 | |

| 5.3 | 11.0 | 1.0 | |

| 5.3 | 15.0 | 1.2 | |

| 5.3 | 15.0 | 1.5 | |

| M6 | 6.2 | 10.0 | 1.6 |

| 6.4 | 11.0 | 1.6 | |

| 6.4 | 12.0 | 1.0 | |

| 6.4 | 12.0 | 1.5 | |

| 6.4 | 12.0 | 1.6 | |

| 6.4 | 12.5 | 1.6 | |

| 6.4 | 14.0 | 0.8 | |

| 6.4 | 14.0 | 1.2 | |

| 6.4 | 14.0 | 1.6 | |

| 6.4 | 18.0 | 1.6 | |

| 6.4 | 32.0 | 1.6 | |

| 7.4 | 14.0 | 1.6 | |

| M8 | 8.4 | 16.0 | 1.0 |

| 8.4 | 16.0 | 1.6 | |

| 8.4 | 17.0 | 1.0 | |

| 8.4 | 17.0 | 1.6 | |

| 8.4 | 17.0 | 2.0 | |

| 8.4 | 18.0 | 1.6 | |

| 8.4 | 18.0 | 2.0 | |

| 8.4 | 21.0 | 2.0 | |

| 8.4 | 24.0 | 2.0 | |

| 8.4 | 25.0 | 2.0 | |

| M10 | 10.5 | 20.0 | 2.0 |

| 10.5 | 20.0 | 2.5 | |

| 10.5 | 21.0 | 1.0 | |

| 10.5 | 21.0 | 1.5 | |

| 10.5 | 21.0 | 2.0 | |

| 10.5 | 22.0 | 2.0 | |

| 10.5 | 22.0 | 2.5 | |

| 10.5 | 24.0 | 2.0 | |

| 10.5 | 30.0 | 2.5 | |

| 10.5 | 32.0 | 1.6 | |

| 10.5 | 50.0 | 3.0 | |

| M12 | 13.0 | 24.0 | 2.0 |

| 13.0 | 24.0 | 2.5 | |

| 13.0 | 40.0 | 3.0 | |

| M14 | 15.0 | 30.0 | 3.0 |

| 15.0 | 44.0 | 3.0 | |

| M16 | 17.0 | 30.0 | 2.0 |

| 17.0 | 30.0 | 3.0 | |

| 17.0 | 50.0 | 3.0 | |

| M18 | 19.0 | 34.0 | 3.0 |

| M20 | 21.0 | 37.0 | 3.0 |

| 21.0 | 39.0 | 3.0 | |

| 21.0 | 60.0 | 4.0 | |

| M22 | 23.0 | 39.0 | 3.0 |

| M24 | 25.0 | 44.0 | 4.0 |

| 25.0 | 50.0 | 4.0 | |

| 26.0 | 72.0 | 5.0 | |

| M27 | 28.0 | 50.0 | 4.0 |

| 28.0 | 56.0 | 4.0 | |

| M30 | 31.0 | 56.0 | 4.0 |

| M33 | 34.0 | 60.0 | 5.0 |

| 34.0 | 66.0 | 5.0 | |

| M36 | 37.0 | 66.0 | 5.0 |

| M39 | 40.0 | 72.0 | 72.0 |

| M39 | 43.0 | 72.0 | 72.0 |