Materials

WE WORK WITH OVER 200 HIGH PERFORMANCE PLASTIC MATERIALS … THE MAJOR ONES BEING

PA 66 (Nylon)

Our standard polymer. The best trade-off against cost for mechanical, temperature and ageing resistance. Supplied in a Natural Colour (which may vary slightly according to material used) most items are available in black by dyeing the original item after manufacture.

PA 66 (Black Nylon)

All the enhancements of Natural PA 66 but with increased outdoor stability and weatherability.

30% GF Nylon (Glass Filled)

Compared with virgin PA 66 this 30% glass fibre reinforced nylon grade offers increased strength, stiffness, creep resistance and dimensional stability whilst retaining an excellent wear resistance. It also allows higher maximum service temperatures.

TPR (Thermoplastic Rubber)

Excellent UV resistance especially in high ozone areas. Extremely pliable without deforming its shape.

PP (Polypropylene) and PE (Polethylene)

For good chemical resistance and pliability. Complies with Food standards. Both materials are available in a wide range of densities.

PC (Polycarbonate)

Highest impact strength over a wide range of temperatures. The best product when transparency is required.

PTFE (Teflon)

High chemical resistance and good resistance to weathering. Known for its “slipperiness”.

PEEK

Heat resistance (up to 180 degrees Celsius) and impenetrable to most chemicals. A high strength alternative to most polymers.

PVDF (Polyvinylidene Fluoride)

Combines excellent cold and hot mechanical strength with universal chemical resistance.

POM (Acetal)

Acetal products are characterised by their strength, stiffness and hardness and are stable over a wide range of temperatures, humidity, environments and stress.High load bearing characteristics – absorbs little moisture.

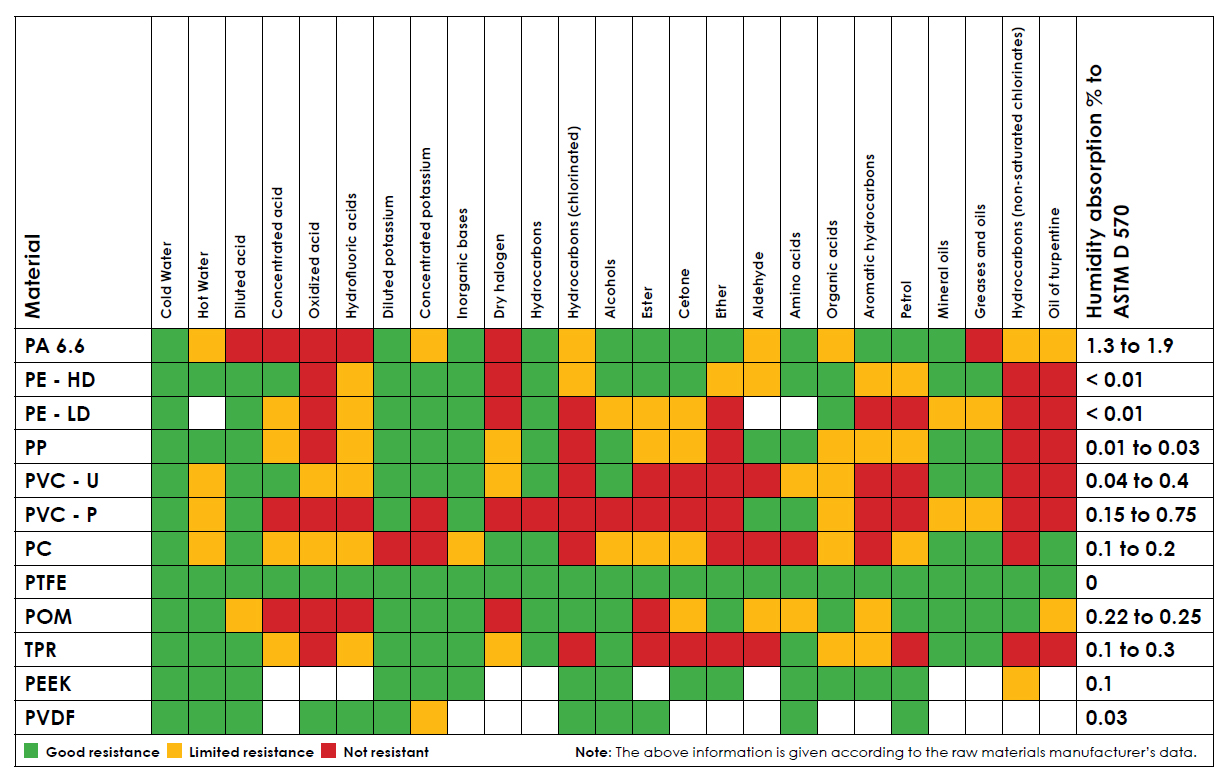

TABLE OF RESISTANCE TO LIQUIDS